Charge a Marine Battery: Step-by-Step Guide

Table of Contents

- Charge a Marine Battery: Step-by-Step Guide

- Understanding Marine Batteries

- Preparing to Charge Your Marine Battery

- Step-by-Step Guide: How to charge a marine battery

- Best Practices for Marine Battery Maintenance

- Conclusion

- FAQ

- Hot Resarch

- Definition of medical device

- The Working Principle of Solar Monitoring System

- Introduction of Solar Monitoring System

- Solar Monitoring System vs Tradtional Monitoring System

- Reasons For The Rise Of Lithium Battery Raw Materials

Marine batteries are the lifeblood of any boat—they power your engine, lights, gauges, and all the essential onboard electronics. Without a healthy battery, your boat is a pretty shell on the water. In this article, we dive into the burning question: how do I charge a marine battery? We’ll explore everything from the ins and outs of battery types to a step-by-step guide on charging. Plus, we’ll compare the advantages of a marine li ion battery with those of traditional marine deep cycle batteries. Let’s get started on this exciting journey to keep your boat powered and your adventures safe!

Understanding Marine Batteries

1. Types of Marine Batteries

Not all marine batteries are created equal. When it comes to powering your boat, you typically have three choices:

- Starting Batteries: These provide that quick, powerful burst of energy to get your engine running, but they’re not built for long-term power.

- Deep Cycle Batteries: Designed for sustained power delivery, these batteries keep your lights, electronics, and other accessories humming for hours.

- Dual-Purpose Batteries: These offer a blend of starting and deep cycle capabilities, which can be handy on smaller vessels with limited space.

Most boaters prefer marine deep-cycle batteries for extended use and reliability. These batteries handle deep discharges better, ensuring their boats stay powered even during extended trips.

2. Battery Chemistry and Technology

Battery chemistry plays a pivotal role in performance and longevity. Traditional chemistries—like lead-acid, AGM, and gel—have long been the go-to options. However, a modern contender is changing the game: the marine li ion battery.

Why choose a marine li ion battery? Because it’s lightweight, lasts significantly longer, and requires minimal maintenance compared to conventional batteries. Think of it as upgrading from an old clunker to an award-winning sports car in the world of batteries. This cutting-edge technology improves performance and enhances safety and efficiency, making it a popular choice among serious boaters.

Learn more about lithium-ion battery technology on Wikipedia.

Preparing to Charge Your Marine Battery

Before you begin the charging process, a little preparation goes a long way toward ensuring safety and efficiency.

1. Assessing Your Battery’s Condition and Type

First, give your battery a thorough once-over. Check its age, inspect for any signs of corrosion, and verify the battery type. Understanding whether you’re dealing with a marine li ion battery or deep cycle batteries is crucial—it influences which charger to use and how you’ll maintain it. A well-maintained battery lasts longer and performs better when you charge a marine battery.

2. Choosing the Right Charger

Next up is selecting the correct charger. You generally have two main options:

- Onboard Chargers: Permanently installed on your boat, these chargers make it super convenient to power up as long as you have access to a standard outlet.

- Portable Chargers: These allow you to charge your battery wherever you are, which is ideal for smaller boats or when space is at a premium.

Make sure the charger you choose matches your battery’s chemistry and voltage. This step is especially important for those opting for a marine li ion battery or deep cycle batteries—using the wrong charger can lead to underperformance or even damage.

3. Safety Precautions Before Charging

Safety should always be your top priority. Here are some key precautions:

- Work in a Safe Environment: Charge your battery in a well-ventilated area and ensure the temperature is within the manufacturer’s recommended range.

- Clean Battery Terminals: Dirty or corroded terminals can interfere with the charging process, so give them a good clean before you connect anything.

- Gear Up: Wear protective gear such as gloves and eye protection to prevent mishaps.

- Follow Manufacturer Guidelines: Always adhere to the specific recommendations provided by your battery and charger manufacturers.

By taking these simple steps, you will ensure your safety and optimize the performance and lifespan of your battery.

Step-by-Step Guide: How to charge a marine battery

Let’s get into the nitty-gritty of charging your boat’s power source. Follow these steps, and you’ll power up like a pro in no time!

1. Cleaning and Inspecting Battery Terminals

Before you plug anything in, clean your battery terminals. Dirty or corroded terminals can prevent your charger from doing its job, and no one wants a slow charge on a hot day!

- Tip: Mix some baking soda with water, scrub gently with a soft brush, and wipe dry.

- Why It Matters: Clean connections ensure that every bit of energy flows efficiently when you charge a marine battery.

2. Connecting the Charger

Now, let’s hook everything up:

- Positive (Red) Cable: Firmly attach this to the positive terminal.

- Negative (Black) Cable: Connect it securely to the negative terminal.

Double-check your connections, whether using a smart charger that adjusts the current automatically or a trusty manual charger. This step is vital, especially when working with a marine li ion battery or marine deep cycle batteries. Once the cables are locked in, plug in your charger and power it up. Easy as pie, right?

3. Monitoring the Charging Process

Keep an eye on your battery as it charges—this is where modern tech shines:

- LED Indicators: These give you a quick look at the charge level.

- Smart Apps & Timers: Many chargers have apps or built-in timers to let you know when you’re full.

By actively monitoring, you prevent overcharging and ensure your battery gets the right amount of juice.

4. Disconnecting the Charger Safely

When your battery is fully charged, it’s time to disconnect—but do it safely:

- Unplug the Charger: Always start by unplugging the charger from the wall.

- Remove the Negative Cable: Disconnect the black cable first.

- Disconnect the Positive Cable: Finally, remove the red cable.

Following this order helps prevent accidental short-circuits and keeps your battery in shape.

Best Practices for Marine Battery Maintenance

Regular maintenance keeps your battery performing like a champ. Here’s how to keep those power levels up!

1. Maintenance Tips for Prolonging Battery Life

- Routine Inspections: Check for any signs of corrosion or wear on the terminals.

- Clean Regularly: A little cleaning goes a long way in ensuring your connections are solid.

- Water Topping: Top up with distilled water when needed for lead-acid batteries.

By following these habits, you’ll always be ready to charge a marine battery and hit the water confidently.

2. Optimizing Charging Cycles

Different batteries have different needs:

- For a marine li ion battery: Enjoy the benefits of minimal maintenance and the ability to handle deeper discharges.

- For marine deep cycle batteries: Stick to regular, shallow discharges to keep them healthy over the long haul.

Tailoring your charging cycle to the specific battery type maximizes performance and extends lifespan.

3. Troubleshooting Common Issues

Even the best-maintained batteries can run into issues. Watch out for:

- Overcharging: This can overheat your battery and cause damage.

- Undercharging: Leaves your battery underpowered.

- Terminal Corrosion: Hinders efficient energy transfer.

If you notice any problems, check your charger settings and ensure you use the right equipment for your battery type.

Conclusion

1. Recap of Key Points

We’ve broken down how to charge a marine battery step by step—from cleaning and connecting to monitoring and safe disconnection. Each stage is crucial for keeping your boat’s power system in peak condition.

2. Final Tips for Maintaining Both Marine li ion battery and marine deep cycle batteries

Whether you opt for the cutting-edge marine li ion battery or the reliable marine deep cycle batteries, proper care and regular maintenance are your best friends. Tailor your charging habits to your battery’s specific needs, and you’ll enjoy award-winning performance on every trip.

3. Encouragement to Follow Best Practices for Reliability on the Water

Stick to these best practices, and you’ll be cruising with confidence. Keeping your battery in prime condition means fewer hassles and more time enjoying your time on the water. Let’s keep those adventures rolling, shall we?

For more detailed battery care tips and industry insights, check out reputable sources like the U.S. Department of Energy or Wikipedia’s battery technology page. Happy boating!

FAQ

1. Can you charge a marine battery with a regular charger?

While you technically can, it’s not recommended. Marine batteries require a charger that matches their specific chemistry and voltage. A regular charger may not provide the proper charging profile, leading to undercharging, overcharging, or even damage over time.

2. What is the best way to charge a boat battery?

The best way is to use a charger specifically designed for your battery type. Follow a step-by-step process: clean and inspect the terminals, connect the positive and negative cables correctly, monitor the charging process using bright indicators, and disconnect safely when fully charged. This ensures efficiency and longevity.

3.What kind of charger do I need for a marine battery?

You need a charger that is tailored to your battery’s chemistry—whether it’s a marine li ion battery or marine deep cycle batteries. Look for chargers with the correct voltage, charging algorithm, and safety features like automatic shut-off and intelligent monitoring for optimal performance.

Hot Resarch

Marine Battery Battery Manufacturer Lithium Battery

Hello

Medical devices refer to instruments, equipment, appliances, materials, or other items used on the human body alone or in combination, including the required software; their effects on the surface and in the body of the human body are not obtained by pharmacological, immunological or metabolic means , But these methods may participate and play a certain auxiliary role; their use aims to achieve the following expected purposes:

(1) Prevention, diagnosis, treatment, monitoring and alleviation of diseases;

(2) Diagnosis, treatment, monitoring, mitigation, and compensation for injury or disability;

(3) Research, substitution, and adjustment of anatomical or physiological processes;

(4) Pregnancy control.

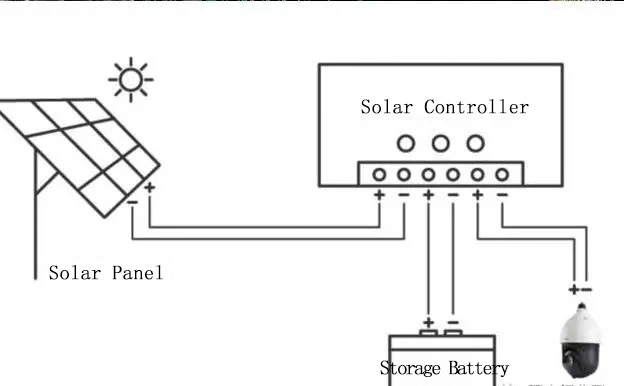

The working principle of the solar energy monitoring system is that solar panels absorb light energy and convert it into electrical energy, and then divide the electrical energy through the controller, provide it for direct use by monitoring and store it in the storage battery, and provide long-lasting power for monitoring.

Introduction of Solar Monitoring System

Table of Contents

I. Solar Power Equipment

1. Solar Panels

(1) Types

The materials of solar panels primarily include: monocrystalline silicon, polycrystalline silicon, and amorphous silicon.

- Monocrystalline Silicon Solar Panels: Photoelectric conversion efficiency is around 15%, with the highest reaching 24%. This is the highest conversion efficiency among all types of solar panels, but they are more expensive to manufacture. Their typical lifespan is about 15 years, with the maximum being around 25 years.

- Polycrystalline Silicon Solar Panels: Photoelectric conversion efficiency is around 12%, and they’re somewhat cheaper than monocrystalline silicon panels. Their lifespan is shorter than monocrystalline silicon.

- Amorphous Silicon Solar Panels: Can generate power even in weak light conditions. Internationally advanced amorphous silicon solar panels have a photoelectric conversion rate of about 10%, and this efficiency decreases over time.

(2) Parameters

- Peak Power: Refers to the power of the solar panel when sunlight is strongest, measured in watts (W).

- Working Voltage

- Dimensions: Refers to the size of the solar panel.

- Photoelectric Conversion Rate: The efficiency of the solar panel in converting sunlight into electrical energy.

2. Solar Controller

The full name is the solar charge-discharge controller. It is used in solar power generation systems to automatically control the charging of the battery by multiple solar cell arrays and the power supply of the solar inverter load by the battery. It specifies and controls the charging and discharging conditions of the battery, and controls the energy output of the solar cell modules and batteries to the load according to the power requirements of the load. It is the core control part of the entire photovoltaic power supply system.

3. Storage Battery

As the name suggests, a storage battery is used to store electricity. It primarily stores the electrical energy converted by solar panels and can be used multiple times in a cycle. In a comprehensive monitoring system, some equipment requires a 220V or 110V AC power source, while the direct output of solar power is typically 12V DC, 24V DC, or 48V DC. Therefore, to provide power to 220V AC or 110V AC devices, the system must include a DC/AC inverter to convert the direct current produced by the solar photovoltaic power system into alternating current.

- Battery Capacity: = Discharge Current × Discharge TimeMeasured in AH: For example, 50AH means it can provide a current of 50A for 1 hour.

- Voltage: Monitoring systems are generally equipped with 12 volt lithium battery.

II.The Working Principle of Solar Monitoring System

1. When the sun is strong, the controller divides the electric energy converted by the solar panel into the one used for monitoring and the one stored by the battery;

2. When the sun is weak, the controller will take out the electric energy from the battery and provide it for monitoring when the electric energy converted by the solar energy is not enough to monitor the normal use;

3. During nighttime or on cloudy days when sunlight conditions are unfavorable, the energy storage system takes over to power the video surveillance.

In addition to sparsely populated outdoors, roads, home courtyards, scenic spots and other places can also be installed with solar monitoring, as long as the solar panels are not blocked by obstructions. It should be noted that the installation of solar monitoring should pay attention to the solar panels that can fully receive the sunlight, the battery also needs to be replaced regularly, and the waterproof cover should be fixed to prevent losses caused by water ingress.

Solar Monitoring System vs Tradtional Monitoring System

- Addresses the monitoring needs of remote areas, as well as regions with no humans, electricity, or network.

- Economical, practical, and reliable.

- Low construction cost, quick installation, short construction time, good safety, and minimal maintenance costs.

- Operates normally during rainy days. Solar power doesn’t solely depend on sunlight to generate electricity; any form of light will do. The system has energy storage devices to ensure it works at night or on cloudy/rainy days.

- The equipment operates with automatic control, capable of unmanned operation and wireless remote monitoring.

- Utilizes specialized monitoring controls and inverter systems. It doesn’t interfere with regular signal transmission and reception for monitoring. Management and maintenance are simple, convenient, and operational costs are very low.

- Employs standalone solar power for wireless transmission, including 4G and WiFi, fully wireless.

- Components are flexible, compact, and easy to install and network.

- Provides both alternating current (AC) and direct current (DC) power supplies to meet various load electricity needs.

- Uses a maintenance-free waterproof lithium battery as the energy storage device, operating temperatures ranging from -40℃ to +60℃, characterized by long life and high performance.

As the market for new energy vehicles and lithium batteries continues to be hot, the prices of upstream raw materials for lithium batteries have risen rapidly. Among them, the cathode material is the most critical raw material for lithium batteries, including lithium carbonate and lithium hydroxide. At present, lithium carbonate, lithium hydroxide, electrolytes, etc. have all increased to varying degrees, and some raw materials have increased by more than 200% compared with the beginning of this year.

Lithium batteries are widely used in electronic products, power storage, and new energy vehicles. Since the beginning of this year, while prices have continued to rise, “difficult to find a single product” has become the current status of raw material procurement by lithium battery companies. Many raw material manufacturers have placed orders for next year.

September to November is an intensive procurement period for my country’s new energy vehicles to stock up at the end of the year. It is expected that during this period, the overall market demand will increase again.

At present, the domestic annual production capacity of lithium carbonate is about 340,000 tons, and the annual production capacity of lithium hydroxide is about 230,000 tons, but the actual output is lower than the production capacity.